Sukup Commercial Drag Conveyors are designed for efficient grain and material handling with features that enhance durability and simplify maintenance. These conveyors come in various sizes ranging from 3432bu/hr to 68967bu/hr and are equipped with heavy-duty chain systems, including the 81XHH, WH124, and WH132 chains as standard depending on the size, with optional upgrades for increased durability and capacity. Constructed with hot-dipped galvanized steel, the head, tail, and trough sections ensure long-term resistance to wear and corrosion. Sukup Drag Conveyors are also customizable to fit your operation and material handling needs.

The head and tail specifications include split-design sprockets and easily removable shaft, bearing, and sprocket assemblies for streamlined maintenance. Trough sections feature a three-piece design with a removable bottom and patented Hip Style Bolted Conveyor Covers, which provide a weather-tight seal while leaving no area for water to leak into the conveyor. With replaceable components such as bottoms, liners, and rails, and a variety of abrasion-resistant material options, Sukup Commercial Drag Conveyors offer superior performance and adaptability for diverse operational needs.

Standard Features

- Exclusive, patented cover design keeps dust in and water out

- Bolted hipped cover

- Bearing, split-sprocket and shaft can be removed as an entire assembly, saving time

- Removable AR bottom can be easily replaced without replacing the entire body of the conveyor

- Externally-mounted, heavy-duty pillow block bearings with bearing and shaft guard on head and tail

- Heavy-duty construction throughout means Sukup Drag Conveyors will last for years to come

- Turned, ground and polished shaft

- 1/2" UHMW paddles eliminate steel-to-steel contact

- Up to 10o incline allowed with double flighting

- Corrosion-resistant Acme thread take-up screws at tail

- Split sprockets standard on some larger capacity conveyors

- 14" and 18" - 81XHH (2.609" pitch) chain standard

- 22" and 26" - WH124 (4.00" pitch) chain standard; upgradable to WH124HD (4.063" pitch)

- 30" and 34" - WH132 (6.050" pitch) chain standard; upgradable to WH150XHD (6.050" pitch)

- Dodge Bearings - Head - S2000, Imperial ISAF or USAF500 (Imperial IP option up to 4 15/16")

- Other bearing options upon request

- Target Chain Speed - 150 FPM

- Hot-Dipped Galvanized - Head, tail and trough sections are all hot-dipped galvanized

- Abrasion-Resistant (AR) 200 or 450 liners on sides, bottoms, and return rails

Product Accessories

- Abrasion-Resistant (AR) bottoms are available up to 3/8" thickness

- AR side liners are available up to 1/4" thickness

- AR return rail liners are available up to 1/4" thickness

- End relief Door prevents damage to the conveyor in the event of a discharge plug

- Reversing Feature can take grain in multiple directions and is a great addition if you are looking to unload into two separate bins

- By-pass drive-over hoppers have an adjustable shroud to control flow and are available in 6', 8' or 10' lengths in standard or low-profile designs using combinations of hopper can achieve pit lengths up to 50'

- By-pass inlet hoppers are available in 3', and 4' lengths with optional liner packages

- Intermediate discharge gates can act as a separate discharge location from the head and are made up of 7 gauge construction

- Hazard monitoring system

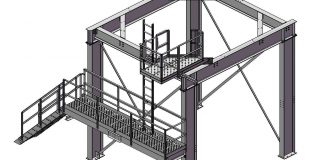

Product Features

- Extremely Gentle on Grain

- Patented Self Sealing & Easy to Remove Covers

- Maintenance Friendly Head & Tail Sections

- A/R Lined Return Rails

Venedocia, OH